The T-slot card pocket method is so called because all but the bottom pockets are created with a T-shaped piece of leather. Typically, a firm vegetable tanned leather (e.g. Buttero) is used with a thickness of 0.8mm to 1.0mm. If the leather is too soft, then the card slots will have a discernible stretch to them and won’t feel right.

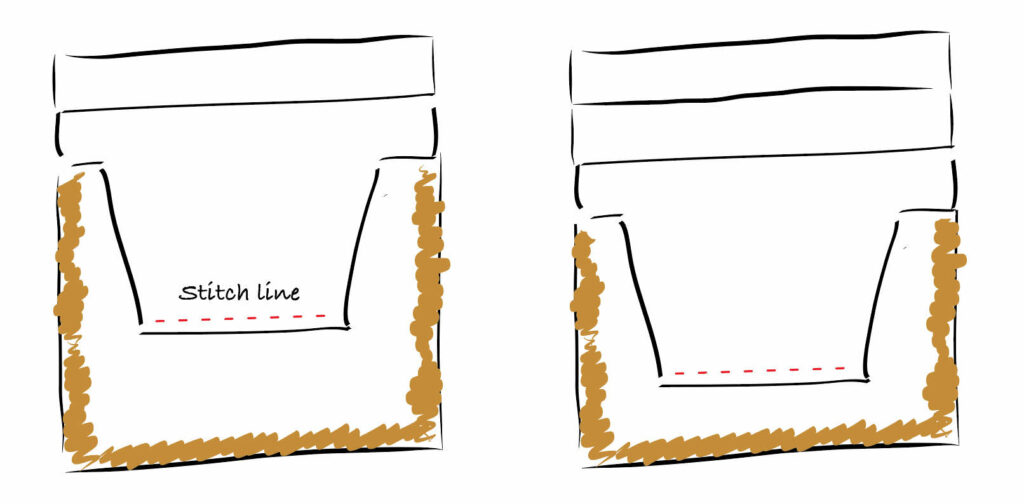

The method is essentially to stack “T” shaped pockets one on top of the other in front of a backing panel, and a stitching line is added at the base of each pocket to act as a stopper for the card behind.

You can design pretty much any pocket you want: straight, slanted, curved, etc. so long as it has a general “T” shape and the leather inside the pocket does not reach all the way to the edge of the compartment. The dimensions of a credit card are 53.98mm (H) x 85.6mm (W) but some gap either side of the pocket needs to be included for stitching lines, as well as some additional space for the cards to slide in comfortably while also remaining secure. Typically, this means that for vertical card slots a final compartment width of approximately 70mm is required; 100mm for horizontal card slots.

Because the T-slots need to sit over one another (and thus slightly curve around the leather pocket underneath), it’s good practice to give some extra allowance (2-5mm) either side and trim the leather down at the end. This also gives you a cleaner edge on both sides.

To avoid ridges, the edges of the bottom of the pocket need to be tapered with a skiving knife and (ideally) the hidden section of the pocket itself should be thinned down with a French beveler or bell skiver. If you so wish, you can also burnish the flesh side of the pocket.

The tops of each card pocket are then edge creased, beveled, and lightly burnished before being attached to the backing piece, starting with the top pocket. To do this it is best to have a printed template to mark the position of the T-slots to ensure they are level.

The backing panel can either have the grain facing the front (most common) or facing the back (as in the photograph below). A backward facing panel means that the compartment itself is all of the same thickness without the “step down” between the top pocket and the other card slots.

Additionally, you can use thinner leather for the backing panel, helping slim down the overall thickness of the card slot compartment. If you’re making T-slots with the grain of the backing panel facing to the front then the thickness should be the same as the pockets themselves.